GEA supplies an extensive array of products and services, comprising laboratory freeze dryers, the two pilot-scale for R&D and tiny output batches; industrial freeze dryers; and full freeze dryer systems.

Biopharmaceutical companies have more and more favoured lyophilization to the formulation of their pharmaceutical products. Mainly, the driving variables bringing about the greater use of lyophilization is the ability to stabilize the drug products and excipients in a reliable matrix, growing the shelf lifetime of the solution. This, combined with the removal of solvents, provides a positive impact on storage and distribution needs.

This video clip demonstrates how the FreeZone Triad Benchtop Freeze Dryer is made to lyophilize the widest assortment of sample varieties: from bulk products, vials and microplates on heated shelves to massive samples in flasks.

A freeze dryer comprises several integral elements, Every actively playing a pivotal job during the process. The primary components include:

Within the intricate dance of sublimation and condensation on the preservation of crucial biomolecules, the value of knowing freeze-drying can't be overstated.

Comparison of scatter in frozen and lyophilized, pulverized samples from fibrotic kidneys. a Representative Masson's trichrome-stained sections of diabetic rat kidneys. Arrows show samples of focal fibrosis.

Throughout sublimation, the temperature must always be stored down click here below the melting temperature with the product or service. If your temperature rises as well speedily or click here if it is way too superior, the merchandise starts to melt which may result in chemical alteration of your product or service, foaming up or puffing in the products cake, lack of risky agents, lack of particles as These are boiled, and/or meltback.

It calls for added elements, which include vials to reconstitute the merchandise. And it needs a sturdy operation and deep experience. "It is just as much an artwork as It's a science," says Glimpse.

Mass transfer then takes place because the sublimation progresses with the area down as resistance to fuel movement increases.

Because the drinking water removal process takes place less than situations where by the merchandise stays frozen, it ensures the integrity and structure from the sample are preserved. It is a delicate nevertheless effective signifies of extracting dampness without the need of compromising the Organic or chemical attributes of the products.

Whether or not you might be in pharmaceuticals, biotech, or maybe the foods industry, knowing these equipment is pivotal. As we delve even more, we'll navigate the extensive landscape of lyophilizers, guiding you toward generating an informed decision that aligns properly with your preferences.

The drug product or service formulation for that reason needs to be optimized to ensure product security and maintain the desired attributes throughout the freezing and drying process.

Herein lies the indispensable purpose of freeze-drying: to make sure the longevity and potency of those necessary healthcare tools.

Stainless steel and product or service integrity: The elements Utilized in the construction of freeze-drying devices, especially the chamber and trays, substantially influence the result.

Spencer Elden Then & Now!

Spencer Elden Then & Now! Amanda Bynes Then & Now!

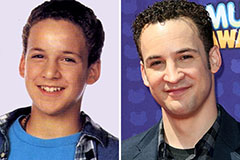

Amanda Bynes Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!